The BMW Project — Looking Back on the First 10 Years in South Carolina

A few months before BMW Group Plant Spartanburg celebrated the 30th anniversary of its groundbreaking and the production of the six millionth BMW built in the United States, three friends sat down to talk about what it took to build the very first car.

In their respective roles representing BMW and South Carolina’s workforce development initiative readySC, each had a hand in the company’s early success:

- Bobby Hitt, BMW Community Relations, managed BMW communications and community involvement and coordinated plantwide events and celebrations such as the plant’s grand opening. He would go on to lead South Carolina’s Department of Commerce until his retirement.

- Sky Foster, BMW Recruiting and Staffing, directed workforce selection and training efforts. She was the 5th employee hired and was responsible for driving the very first car onto the stage at BMW’s grand opening. She went on to become manager of BMW corporate communications until her retirement.

- Susan Pretulak, readySC area director for the Spartanburg region, spearheaded South Carolina’s recruitment and training endeavors on BMW’s behalf, including development and oversight of several training centers in the area. She went on to become VP of Economic Development for South Carolina’s Technical College System until her retirement.

This tells the real story behind BMW’s first years in South Carolina: the initial skepticism of South Carolina’s selection as the location for BMW’s first major manufacturing facility outside of Germany, the recruitment and training of a workforce eager to build BMW’s, the celebration of the first car coming off the assembly line in 1994, and the company’s unparalleled success and profound impact on the community and the state.

Susan Pretulak: I just wanted to say from the bottom of my heart, I was looking forward to this conversation, to seeing you all and to reminiscing about some of the things that we did here and how it affected the rest of the state that we're proud to be part of.

Sky Foster: Ever since the beginning, we have never stopped turning dirt at BMW, so it is a seed and the growth is just phenomenal.

Bobby Hitt: People would ask me what's it like to work for BMW, and I'd say, 'We make high performance cars and it's a high performance workplace, and if you can't keep the pace you're going to fall on the wayside.’

Susan: That's kind of like readySC.

Bobby: And it pretty much never slowed down.

Susan: Failure is not an option. You know it was a baptism by fire a lot a lot of days.

Sky: And drinking from a water hose. Because it took collaboration, and it took partnership.

Susan: That goes to the whole team thing. I mean, we really have known each other for years and learned from each other.

Sky: And I can't thank readySC enough for your flexibility, your support, your commitment, your dedication to this project because it was eyes on this project every day, all day long.

Bobby: It's been the most remarkable project in South Carolina, and we have had just a basket-full of remarkable projects since, but this was the change agent.

Susan: It certainly was.

Bobby: This was the change for South Carolina.

How it Began

Bobby: Well it was exciting for me because my perspective was: here is this remarkable company coming to South Carolina, and I was in the background before it was announced. So I was meeting with the planning department and I'm a former reporter, so I can't help but want to know what's the real reason we came to South Carolina? And the guy looked at me and says, 'Well you know, you've got the two most essential ingredients in car manufacturing.' He says, 'You have a remarkable technical education system.' This is true, I'm not making this up. 'And you have the ability to help people create the skills necessary to build a car, and we've looked at all the other states.'

And I'm going to tell you at the time they were telling me -- the Germans -- that our system in South Carolina was head and shoulders above everybody else. We've always touted readySC as a strong program but here was a validation by a third party and I was pretty impressed with that.

So he says, ‘You have the ability to create skill and that's an essential ingredient in car manufacturing. And I said, ‘What's the other one?’ And he said, ‘It's emotion, it's an emotional product. And we rode around the neighborhoods, and we saw how people kept their yards and how they maintained their houses and that told us that people here are very prideful. And if you mix skill and pride, you get a craftsman. That's what we were looking for.' And in fact, what we found with South Carolinians was that they were remarkably adaptive to this work and emotionally attached to the product.

Sky: So that was an attraction unto itself, BMW coming to South Carolina at the right time because textiles was going down.

Bobby: Had gone down.

Sky: And we picked up there and it has been up ever since.

“And I got a call from a reporter for the International Herald Tribune and his opening line to me was something like, 'Could you tell me why a sophisticated company like BMW would locate in some a backwater place like South Carolina?' And you know my dad used to always tell me, ‘rather than being angry, humor works pretty well.’ And I said, ‘Well you know, after we got these boys and girls wearing shoes they turned out to be pretty good automakers!'”

— Bobby Hitt, South Carolina Secretary of Commerce, Retired

Susan: Do you guys remember the presentation that Ben Davis from the Employment Security Commission used to do about the net loss of textile jobs and the net gain in the automotive sector, and it was almost equal? It was so close to equal, and I remember thinking, 'Good Lord, if BMW had not located here, what would we be doing here in the upstate of South Carolina?

Sky: One of the things that I was thinking about as one of the concerns at the time was, ‘can textile people actually build cars?’ The one thing they forgot was the resilience of our people and the fact that textiles taught them--

Bobby: Show up to work.

Sky: Repetitive work.

Susan: Physical, mechanical.

Sky: Exactly. So all our people wanted to know is what do we need to do, how do you want it done? We will get it done.

Susan: Exactly.

Bobby: Right, yeah. And we started out with the world media saying that BMW made this fantastic mistake. They had termed us almost like a third world country here in South Carolina. And I got a call from a reporter for the International Herald Tribune and his opening line to me was something like, 'Could you tell me why a sophisticated company like BMW would locate in some a backwater place like South Carolina?' And you know my dad used to always tell me, ‘rather than being angry, humor works pretty well.’ And I said, ‘Well you know, after we got these boys and girls wearing shoes they turned out to be pretty good automakers!' (laughter)

And the community was amazing toward us. When we were very early days, we decided to get everybody a t-shirt that said BMW and so like 100 people got this t-shirt. And if people were in the mall wearing that t-shirt people would come up to them and congratulate them like they'd won the lottery. The level of excitement in this community--

Susan: That's true.

Bobby: --over BMW choosing South Carolina was unfettered. I mean it was amazing.

Susan: When we used to do those pre-hire classes, and Bobby, I know you'll remember this too from our work with other prospects, you know they're like, 'Oh, no one's going to come to these pre-hire classes.' They came to those pre-hire classes with bells on!

Bobby: Oh yeah.

Susan: We wouldn't even have the room set up and they'd be in there twiddling their thumbs like, 'When am I gonna start? When am I gonna start?' And that quality about our workforce, Sky, has been for me one of the great gifts of working economic development in South Carolina, that South Carolinians really were willing to--

Bobby: They want to work.

Susan: --yeah and they wanted to take that extra mile. And if you recall, there were multiple training centers--

Bobby: Correct.

Susan: --just because of the sheer volume of folks.

Bobby: Well, you may recall, 60,000 people applied for the jobs at BMW, it was like, 'oh my God!'

Susan: And there was no electronic application, like an excel spreadsheet or a database. The things that we had to do were extremely manual. And I know Sky knows this very well, that applicant pool was the size of a small city and so anything that could take place in a small city could take place in that applicant pool. I mean it was a lot.

Bobby: Exactly. and all of it was fairly complicated. I remember the first sheet I saw, process sheet for hiring--

Susan: I think at one point there were 20 steps in it--

Bobby: Oh wow, I just remember it being about 10.

Susan: --before you even got to the point where you might be in the plant.

Sky: Exactly. And that's why dwindling down those steps that were in place at the time was necessary just to make sure you got to the right person, because this was huge. And the expectations for BMW in South Carolina were high.

Bobby: Huge. Unbelievable.

Sky: So we didn't want to wave on any talent. We wanted to make sure that we had the right person do the right thing at the right time.

Bobby: In addition to that, we were very focused that we were going to have a diverse workforce.

Susan: Absolutely. You did a great job with that.

Bobby: And the great reality is the German culture gave us the tool we needed to have that diverse workforce in that we measured every month. Every month this lady (indicating Sky) or someone came into senior management and said these are our numbers. And we worried about those numbers, and we wanted those numbers to be correct. We wanted the inside the plant to look like the outside. We were starting with a fresh piece of paper so to speak and if we just pay attention and we decide this is what we want to do we should be able to do it. And we did it. And it was pretty remarkable.

Sky: We wanted it to mirror the community that we lived in.

Bobby: Correct, correct.

Susan: And then what we also learned from you all is that a startup is an incredible opportunity to take the best of the mothership and then add whatever it is that you want to add to that. And we were able to bring a lot of things that maybe you wouldn't have done in Germany, but we could do them here because we were fresh and brand new.

Facing Challenges

Sky: We weren't so concerned about problems because that's what we do every day.

Bobby: Problems are why we're here.

Sky: We have to figure it out and make it work--

Bobby: And move on.

Sky: And then it may change tomorrow but you have to change with it.

Bobby: Yeah.

Sky: So you have to be flexible and agile as we say as a part of our mission, and we really mean it.

Susan: We had the right people, we had the right resources, and I will say this in all compliments to Sky, I often would cite her as the perfect point of contact. You know how, Bobby, we would always talk about in prospect presentations we need a single point of contact.

Bobby: (nodding) Single point of contact.

Susan: And Sky was my single point of contact. She really did that job well because there was no problem that we couldn't talk about and say, 'All right I'm going to talk to these folks on my side and she would go to talk to whoever and then we could come back and solve the problems.

Sky: The other piece of complexity that we had, Bobby, you know so well, we hired non-automotive people. We hired automotive people. We hired people with the Japanese team influence.

Susan: Very different.

Sky: We hired several people from different automotive OEMs. And trying to blend all of that together to get this done? Because everyone felt that they knew the best way to make a car. How do we blend this? It was a huge challenge.

Bobby: It was a challenge. And we had external issues we had to deal with, to communicate with, as well as what y'all were working on. The political view from my side as the political guy was South Carolina gave us these incentives, which we were getting beat up for at the time, and we should be hiring South Carolinians. And so we actually said we were only going to interview people who had lived within a 50-mile radius on the day that the project was announced, so if someone moves in they weren't included.

Susan: And to your point, we frequently had folks spending the night in the parking lot of the training center in hopes that we would take them on as applicants because they lived in Montana, or they lived wherever. I mean the energy behind this project went far beyond that 50 miles. So making that commitment to the state and to the taxpayers was huge. It was huge in terms of how smoothly this project ran.

Bobby: At the same time, we had a lot of corporations in the upstate that were very anxious. There were concerns that whatever we did was going to change all the wage scales and change the whole dynamic of the upstate. And our team organized an event where we brought the CEOs of most of the major companies in the upstate together to tell them what we were going to do, and what we were going to pay, and what our takedowns were going to be and so forth and so on. And it was fascinating because it worked. And everybody was calm. Because they realized we're only going to hire a few hundred people to start with.

Sky: I think that eased their minds. They were thinking you're not taking my entire workforce.

Bobby: Correct. And we also made sort of an informal pledge, that we will monitor it and we will not take too many from anybody. We're not coming to your house to recruit your workers. If they come to us, we will try to moderate how many of them come at one time.

Training the Workforce

Bobby: We couldn't have done it without the training. And of course, readySC, or Tech Special Schools as it was called at the time, it was the key.

Susan: Absolutely.

Bobby: Because you've got to put the car together.

Sky: They were the bedrock of this organization in terms of designing, customizing the training that we needed. (indicating Susan) Because the question you'd ask is, ‘What does success look like? What do you want? How can we deliver it?’

Susan: I can remember looking at your training plan. There would be a time every year where we would sit down and we would look at what needed to be accomplished.

Sky: And we'd all get together, put our heads together, and say 'We need this, this, this and this. And we designed with the technical colleges and all of a sudden, you have a program. And it's customized.

“And you know, one of the things that I think you all brought to the table which ended up being really important for the labor force in South Carolina is the idea of soft skills. It's never been my favorite term, but those skills that go beyond the technical skills. I feel like for readySC, our first foray into understanding the culture of a company, what makes that company run in its heart, we really worked with you on doing that.”

— Susan Pretulak, Susan Pretulak, Vice President of Economic Development, SC Technical College System, Retired

Susan: We worked together for almost 10 years on that project, so we're talking about a lot of a lot of conversation around what's needed and how do we deliver it, because what needs to take place to build in a high-tech environment is pretty comprehensive.

Sky: And you were flexible enough to where if we said, 'Okay we need to tweak it a little bit,' then we'd tweak it a little bit. Because it was trial and error, 'You really want this, you really need this.' The product will drive you into the direction that you really need in terms of how to train the individual, so it was just a phenomenal partnership.

Susan: And you know, one of the things that I think you all brought to the table which ended up being really important for the labor force in South Carolina is the idea of soft skills. It's never been my favorite term, but those skills that go beyond the technical skills. I feel like for readySC, our first foray into understanding the culture of a company, what makes that company run in its heart, we really worked with you on doing that. So things like problem solving, communications, team building, effective meetings--

Bobby: Effective meetings! Oh yeah. How to attend a meeting.

Susan: Exactly. We were having people come in here who've been on a plant floor who had never been in a meeting in their life. Which was a huge empowerment for the workforce.

Sky: We wanted high performance work teams.

Susan: Yes!

Sky: And speaking of soft skills, this curriculum was designed for one full year of training for every associate.

Susan: I still see that graphic in my mind.

Sky: And to pull that off with hundreds of associates, having to plan because the work still has to be done on the line. So we had to pull a few people from each work cell and have the classes established. But one full year was your curriculum on soft skills. That's how important it was to have high performance work teams.

Bobby: The other thing that sat at the middle of it was a policy that I had never encountered in any other company before. It was called 'dignity for the individual.' So if I got mad at you and I cursed at you, I better hope nobody else heard me because the cops would come (indicating Sky and laughing). My point is we can't build the finest product in the world if we can't talk with each other. That's why communications was important. I've got to be able to talk to this person, 'Hey. we got a little problem here with a gas cap thing,' rather than this person saying, 'that ain't my problem, that's your problem.'

Sky: That's the reason for those soft skills classes.

Bobby: Yeah, that's why soft skills was so important.

Susan: Yeah, and we ended up taking it -- and by 'we,' I mean the collective ‘we’ -- taking it further, because we also extended that same core curriculum on the soft skills side to your supplier network. So that essentially you had folks that were working off-site that had comparable skills in terms of communications, team building and things of that sort, which was a remarkable addition to the to the workforce in the upstate.

The First Car

Sky: One of the proudest moments I think I have in our connection together as we have gone through this process, was walking into the plant as we're beginning to build the very first car. And for me it was an aha moment, it was a high-five moment, it's like, We did it!

Susan: We did this.

Sky: We did it, we hired the people, they were trained in Germany, now they're here--

Susan: And here’s a car!

Sky: --building the first car. And emotional, you're talking about emotion?

Susan: It still gives me chills.

Sky: When that car came off the line, it was one of the proudest moments for me. Then to celebrate that moment, we were on the stage that night for the BMW opening ceremony.

Bobby: Yeah, we had the whole plant on the stage.

Susan: Yes. yes!

Sky: It was a perfect night, the temperature was just right, the sky was perfectly starry and the ceremony was beautiful. And for me to drive the first car out on stage...

Susan: Yes!

Bobby: She did.

Sky: It's a moment that I will never, ever, ever forget. And passing those keys over to Dr. Ponka? It was wonderful.

Bobby: It was a terrifying moment for me in that event that I've never talked about publicly but now's a good time as any. We had a big video screen behind the stage, lighting and AV and everything. There wasn't enough power in this building to run the show that we were putting on, so I had to bring in power. We found these generators that they use on movie sets that are called whisper generators, they make no noise.

Susan: Really?

Bobby: But they're running a gasoline engine and they're generating power and we parked them right behind the Zentrum, what is now the parking lot there. And I was just terrified about the whole thing. We had too many variables, and we had 13 stations broadcasting live from here and we closed down the interstate because of the fireworks. We figured people would run off the road. I mean it was a major event, a lot of stress on my team at that time and certainly on me.

And so I'm just walking around worrying about stuff and I walk up to one of these generators and it really is quiet. I open the door and the engine's running and I'm like, ‘Wow, that's amazing,' and then I looked at it and went, 'Oh my god!' It had Mercedes Benz engines in it. I shut the door, did the handle, and turned around to one of my staff and said, 'Get over to the hardware store and get me a couple of padlocks please.

Susan: (laughing) That's a great story.

Bobby: Because all I could think of was Dr. Ponca or one of those would come by and open the door out of curiosity and see that Mercedes engine, and then I'd have to go work for KIA or something like that. (laughs)

Susan: Exactly, or something like that.

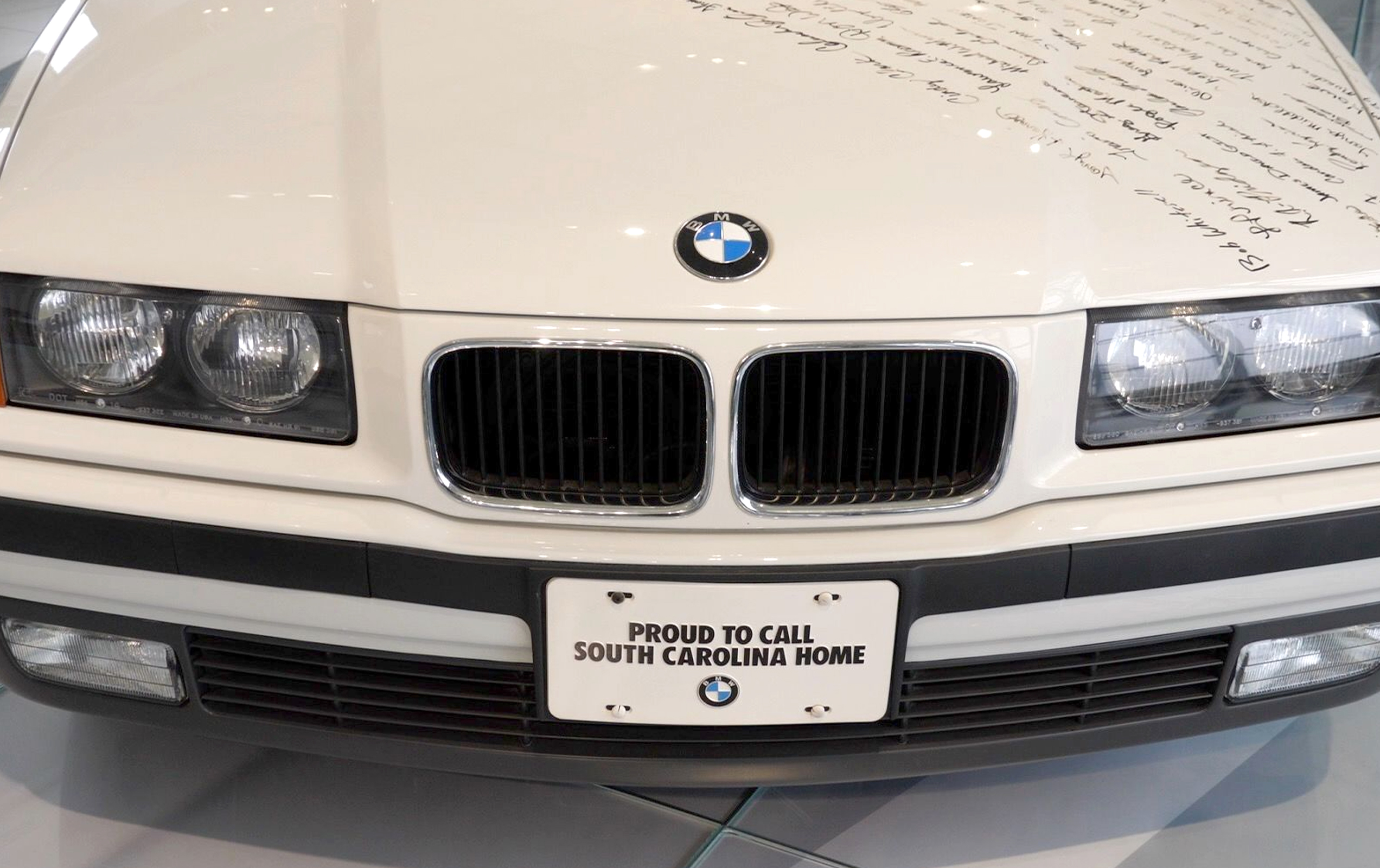

The first of over 6 million BMWs to be manufactured in South Carolina.

The BMW Z3

Bobby: There’s one other thing that I think dramatically impacted all the people in the plant, because we were still small enough that when we did things, we brought everybody together. In 1996, when we launched the Z3 and did the worldwide launch from here, the chairman of the company came over, Chairman Pischetsrieder. We had everybody in the cafeteria, about five, six hundred people, and he basically got up and praised everybody for all the work they'd done to get to this point. And he said, ‘Now you've got to do it every day and you've got to do it faster and better. And oh, by the way, the whole world is watching, and the fate of our company is in your hands.’ And the emotion in the room was like, you could see the blood running out of people.

Susan: No pressure.

Bobby: But it impacted us because we were doing something that no one else had ever really done on that stage in South Carolina. We were presenting something that would in fact become part of the image of South Carolina and the Z3 was it, and what a snazzy little car to do it with.

Susan: It was a snazzy little car.

Bobby: And it was magical quite frankly, and all of a sudden, the world press went from, ‘can they make it good enough’ to ‘can they make enough,’ and no one's ever criticized this plant again.

Susan: Right.

Bobby: But it's amazing today when you realize in our first full 12 months of production we made 28,000 cars and we thought we were stuffed. We were stuffed! Now we make 28,000 cars every two weeks I believe.

Sky: 442,000 a year.

Susan: Yeah, I was about to say.

Automotive Takes Off

Bobby: Yeah. It's almost hard to believe that on a given workday there can be up to 10 or 11,000 people on this site. That's just mind-blowing. And then you go over to our supplier system which is about 30,000 people. So between this one project there's 40,000 or so employed in South Carolina at higher manufacturing wages. And as a result of it, it started attracting other automotives. So when we started there were essentially no automotive manufacturing assets in South Carolina. Today, there are 500 automobile manufacturing-related companies doing business in South Carolina.

Susan: The other thing I would be interested in hearing from you all, after we were able to kind of look at it and say, ‘we’re in good shape here, this is a finely oiled machine,’ what we began to notice is that it wasn't just our state that was interested in what we did. It was our competitors (in other states) as well. And in my opinion the project that we did here helped to bring automotive to the Southeast – and that's why I'd like to know how you feel about it. We got calls from our competitors after their announcements to say, 'Could you help us understand what it is that you did?' Did you see any of that from your seats?

Sky: Of course. I mean our competitors actually came here.

Bobby: Came here and went through the plant.

Susan: To our training centers.

Bobby: We had to get permission to bring them here.

“They were so interested in how we did it. And one visit after the other, every week of our existence, coming here to see what's going on, from reporters to media. Because I think we were always in a state of possibility. What's possible? What's next?”

— Sky Foster, BMW Manager, Corporate Communications, Retired

Sky: They were so interested in how we did it. And one visit after the other, every week of our existence, coming here to see what's going on, from reporters to media. Because I think we were always in a state of possibility. What's possible? What's next?

Bobby: That's exactly right. And I will also say when Boeing was looking, they came here and they looked at what we did in this factory and they went, 'Yeah, we can do it here.' So we became a validation.

Seeing the Impact

Susan: My old colleague Kathie Neeley used to say the best part about a readySC job is you can drive around and you can see what your impact is in the community. And I think that's the gift we've been given, to drive down 101 and say, ‘did you think this would look like this?

Sky: It's so exciting to go to downtown Greenville or Spartanburg and you hear

the different languages.

Bobby: Oh absolutely, yes, you're right.

Sky: Spanish and Italian and French and German and Chinese and all the cuisines around those languages. It has literally changed our community. And I take pride in knowing that BMW had a little staple in making that change.

Bobby: The point is, we demonstrated to the world what South Carolinians can do and it doesn't need to be demonstrated over and over again, it's been demonstrated. We build very sophisticated stuff here now.

Susan: It gave me personally, and I believe my colleagues as well, an incredible amount of confidence that it was doable. And I will say also that the learning that we took away stood us in good stead when we worked with other large companies. It's like, 'Okay, we get this, we understand.

Bobby: We would have never – and I use the word 'we' for meaning South Carolina – we would have never pulled off Boeing had we not pulled off BMW.

But the secret sauce from my point of view as the recruiter was readySC, in that I would tell people, 'if you come here…' And we were recruiting people from halfway around the world. We led the country for most of the last 10 years and we're in the top five in international recruitment, so we had a lot of international companies, I mean just look up and down the interstate here. And they came here because we showed the discipline that we could build a workforce to make them money and that's what I would tell them. 'If you come here and you invest in South Carolina, we will invest in our people and we will train them to make you profitable.' And that's what we've done.

Proud to Call South Carolina Home

Susan: Your company took up the mantle of being a citizen of South Carolina as well. And isn't that the end goal? I mean isn't that what we want for every company that comes here?

Bobby: We built ourselves into the fabric of these greater communities. It stayed that way and I think it's still that way today.

Sky: (indicating Bobby) And there developed the term that you came up with, 'proud to call South Carolina home.’

Bobby: (nodding) Proud to call South Carolina home. And that sort of drove the whole concept of what our community relations and what our community communications and everything should look like and what the personality of BMW should be. And in fact, I used to say that we sort of became a bit of a hood ornament for the state and the two brands are inextricably tied.

Susan: And I'm just going to say this. It's going to sound a little sentimental, but I live pretty close to this plant and across time I still drive by and say, 'Wow, it's just amazing what it's brought to this community.' It does make me a little South Carolina proud.

Bobby: BMW was the high hill that changed South Carolina. This project was the high hill that we had to conquer in order for everything else to occur.

Susan: I agree, Bobby.

Bobby: Prior to BMW we did not have the level of energy we have had now for 30 years and the success-- if we had failed, oh my god.

Sky: Oh it wouldn't be the same.

Bobby: But the success of BMW changed South Carolina. We went from the little engine that couldn't to the little engine that could, and all of a sudden we didn't believe anything was out of our grasp as a state.

Sky: And I still think we are in the beginning. I don't believe we have seen yet what this company is going to do for the world. It's an exciting place to be.

Bobby: Oh, it's terribly exciting, and it was all so personal for all of us.

Susan: And I think about what a gift it was to me. The lessons that I learned here and the people that I worked with held me in good stead professionally for the rest of my career.

Bobby: It was just an amazing place to work and amazing relationships were built here that transcend time. And the reality is everybody won, and our lives have been changed.

Sky: We weren't afraid of problems and trouble. We hit them head on, and we did it.

Bobby: And we all must have done okay because we all made it all the way to retirement. (laughs)

Sky: (laughs) We didn't get kicked off.

Bobby: (laughs) We didn't get kicked off the team.

From groundbreaking to first car in 23 months, BMW’s South Carolina plant was the fastest automotive factory star-up in automotive history.

Special thanks to:

Sky Foster, BMW Manager, Corporate Communications, Retired

Bobby Hitt, South Carolina Secretary of Commerce, Retired

Susan Pretulak, Vice President of Economic Development, SC Technical College System, Retired

Filmed by readySC on February 23, 2022, at the BMW Zentrum in Spartanburg, South Carolina